Delta's Energy Management System (EMS)

Share

Delta's Energy Management System (EMS) efficiently collects data on energy usage and operations from on-site sources, categorizing energy consumption by subcomponents and areas. It offers real-time monitoring, detailed data analysis, timely reporting, precise control, maintenance, production management, and predictive insights. Additionally, it enables in-depth analysis of demand trends, energy usage structures, cost assessment, energy performance indicators, and carbon emissions. These analyses inform actions such as demand control, optimization of related factors, and energy-saving measures, enhancing overall energy management efficiency and sustainability.

Our Solution Offering

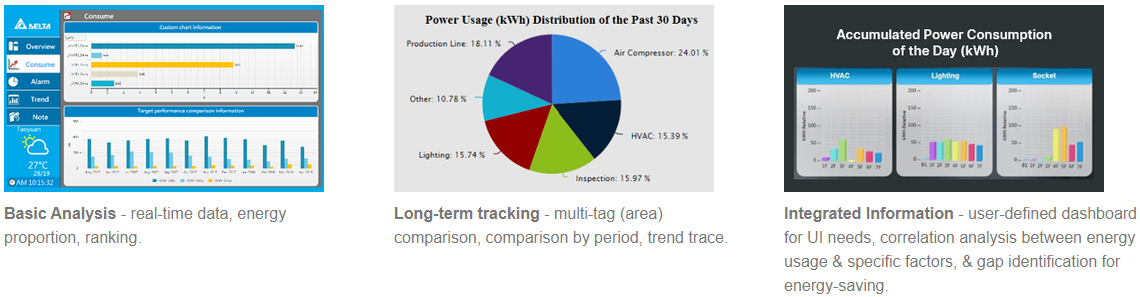

Energy Visualization

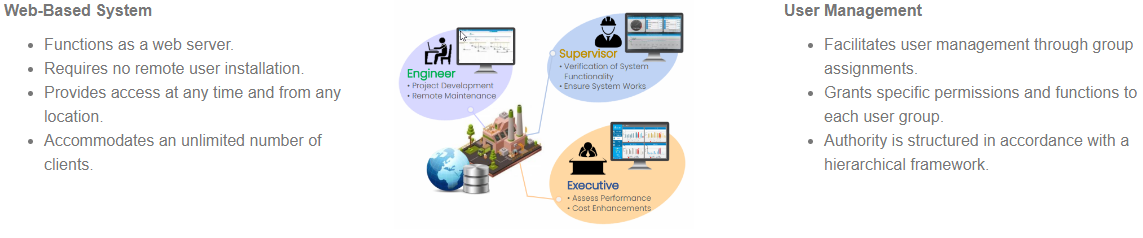

Operation & Authority

Explore Our Solution Benefits

Short-term

Energy Efficiency - Immediate gains in energy efficiency by identifying and rectifying wasteful energy practices and equipment usage.

Production Optimization - Real-time data allows for better production scheduling, reducing downtime, and improving overall productivity.

Mid-term

Energy Optimization - Continuous monitoring and analysis lead to ongoing energy optimization, fine-tuning processes, and reducing energy waste.

Life Cycle Monitoring - Tracking energy consumption over the lifecycle of equipment and machinery, facilitating timely maintenance and replacement decisions.

Environmental Compliance - Better control over energy usage to meet environmental regulations and reduce carbon emissions.

Long-term

Cost Optimization - Sustained reduction in energy costs, leading to improved cost competitiveness.

Energy Savings - Cumulative energy savings over time contribute to significant cost reductions and improved sustainability.

Predictive Maintenance - Early detection of equipment issues through data analysis, reducing maintenance costs and downtime.

Data-Driven Decision-Making - Demonstrating commitment to sustainability and efficiency, potentially attracting environmentally-conscious customers and investors.

Risk Mitigation - Reduced exposure to energy price volatility and supply chain disruptions by proactively managing energy usage.

Continuous Improvement - A foundation for ongoing improvement initiatives, driving further efficiency gains.